AAA-1 Masonry & Tuckpointing is renowned for its exceptional masonry restoration work. We take great pride in what we do, and judging by the letters and comments we receive our clients do too! If you've clicked through our web pages and landed here, then chances are good that you're more than little curious about masonry restoration. So I thought it would be fun to walk you through the process of what we do in a single photo taken from a recent project (see below).

On the left side of the photo is a mostly untouched 120-year-old masonry building. Although underutilized for years, many of the bricks in this building remained in a structurally sound condition (bricks close to the ground where the snow and rain have collected for years have not fared as well). All the way on the left side of this photo (Area #1) you can see a portion of the wall as we found it. The bricks on this wall have become dark with age, pollutants and weather. The mortar joints have been tuckpointed over the years with repeated applications of mortar but this method of repair has not improved the condition of the wall in any lasting way.

Once the bricks were deemed to be structurally sound, we carefully stripped the outer wythe of the wall. Thanks to the forward-thinking building methods employed by the original builders, we were able to safely remove these bricks without catastrophic failure of the back-up wall … even 120 years later! You can see the portion of the wall with the outer wythe of brick removed in Area #2.

Once these bricks were removed, they were carefully inspected to verify their condition. After grading and sorting, the bricks then underwent a gentle but very thorough cleaning process to remove all that grime. The transformation from dirty brick to clean re-claimed beauty was quite incredible!

Once dry, these bricks were used to rebuild large sections of the adjacent building (Area #3). With these reclaimed beauties, new windows and new stone windowsills, the restored structure on the right is not only breathtakingly beautiful but also should last another 120 years!

We really enjoy breathing new life into old buildings, but that's not all we do. We also grind out and tuckpoint mortar joints, replace lintels and shelf angles, caulk windows and doors, and fix and seal new brick-and-concrete block construction (which is how most of the homes and buildings in the last 20 years have been constructed). Let our licensed masons assist you with your next project and get ready to be pleased!

—Rob

Post: Unique Flashing Detail

Monday March 21, 2016

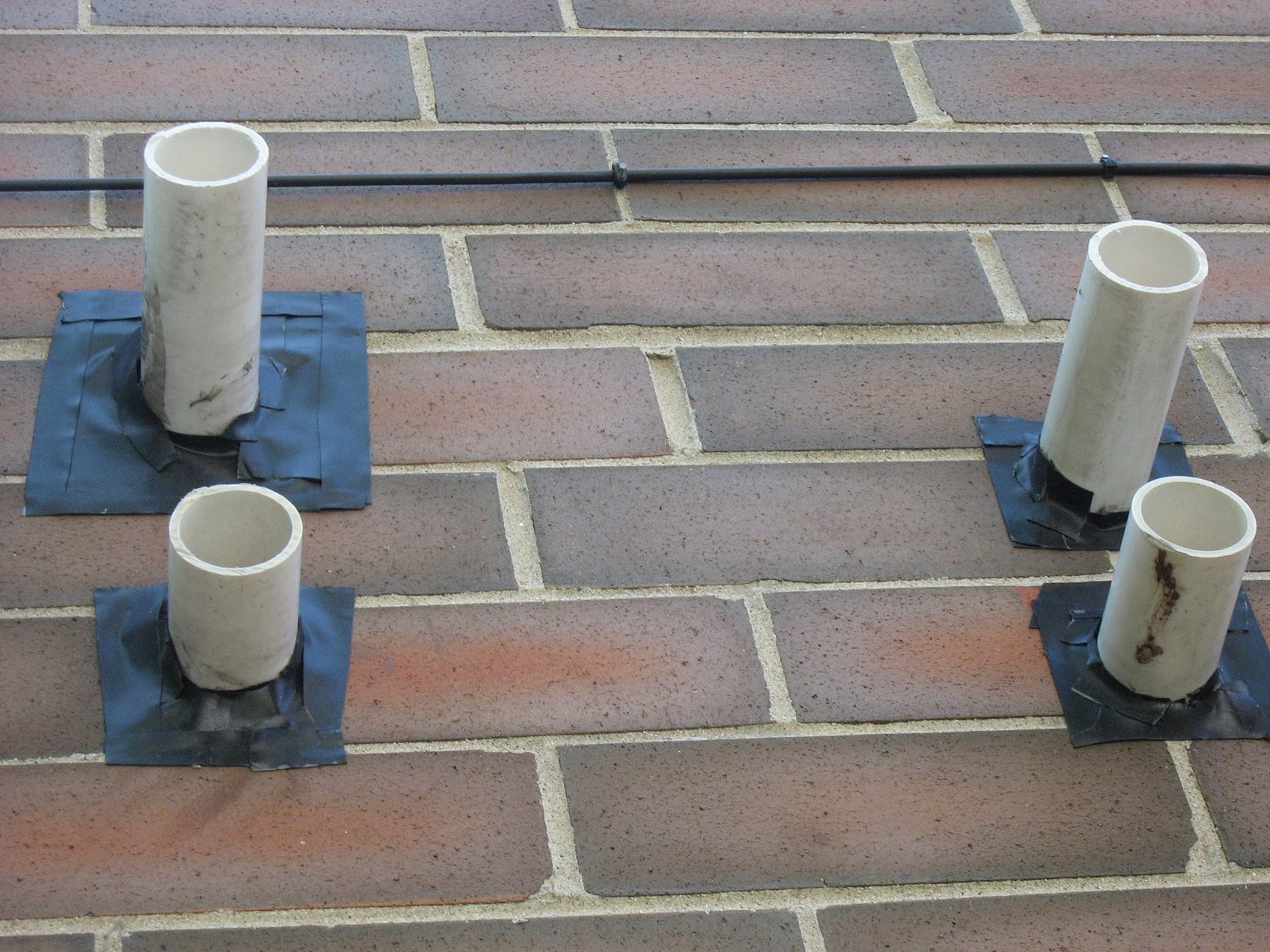

We use flashings to stop water from infiltrating masonry walls.

Seasoned AAA-1 Masonry project manager, Brent, recently photographed this flashing "detail" observed on a client's newer masonry wall. Although the intentions of the original installer may have been sincere, this is a pitiful attempt to prevent water from from penetrating into the wall cavity through the gaps between the round white PVC tubes and the bricks. Frankly, it looks like something my 7-year old might have constructed during a school art class.

The proper method of sealing gaps between wall penetrations (e.g., vents, electrical conduit, etc.) requires the use of primer, backer rod or bond-breaker tape, and high-quality caulk (not surface-applied adhesive as in seen in the photo).

If this condition were to go uncorrected for any period of time, the flashing would begin to peel off and serious water infiltration would result, likely evident in the form of damaged drywall, electrical shorts, rotted floor joists and/or warped floors.

If you would like one of AAA-1 Masonry & Tuckpointing's seasoned project managers to inspect your home for damage (or ridiculous workmanship like what Brent found here), please do not hesitate to call us at (773) 622-7300. We are here to help!

Thank you for the opportunity to be of service.

-Rob

Post: Valentine's Day Truth

Sunday February 14, 2016

I met my wife at a bucolic summer camp in rural Maine when we were still teenagers. We dated all through college and graduate school, and will have been happily married for 13 years this July. My wife knows and accepts (more or less) that from March through December, when the nighttime temperatures push past the freezing mark with consistency, my love for her must be shared…with vintage brick, hand-molded terra cotta, and 19th-century limestone. That's just the way it is when your occupation is masonry restoration. And even when the mercury outside is 7 degrees like it is today, the men and I are meeting with building owners and property managers, diagnosing and troubleshooting their masonry issues.

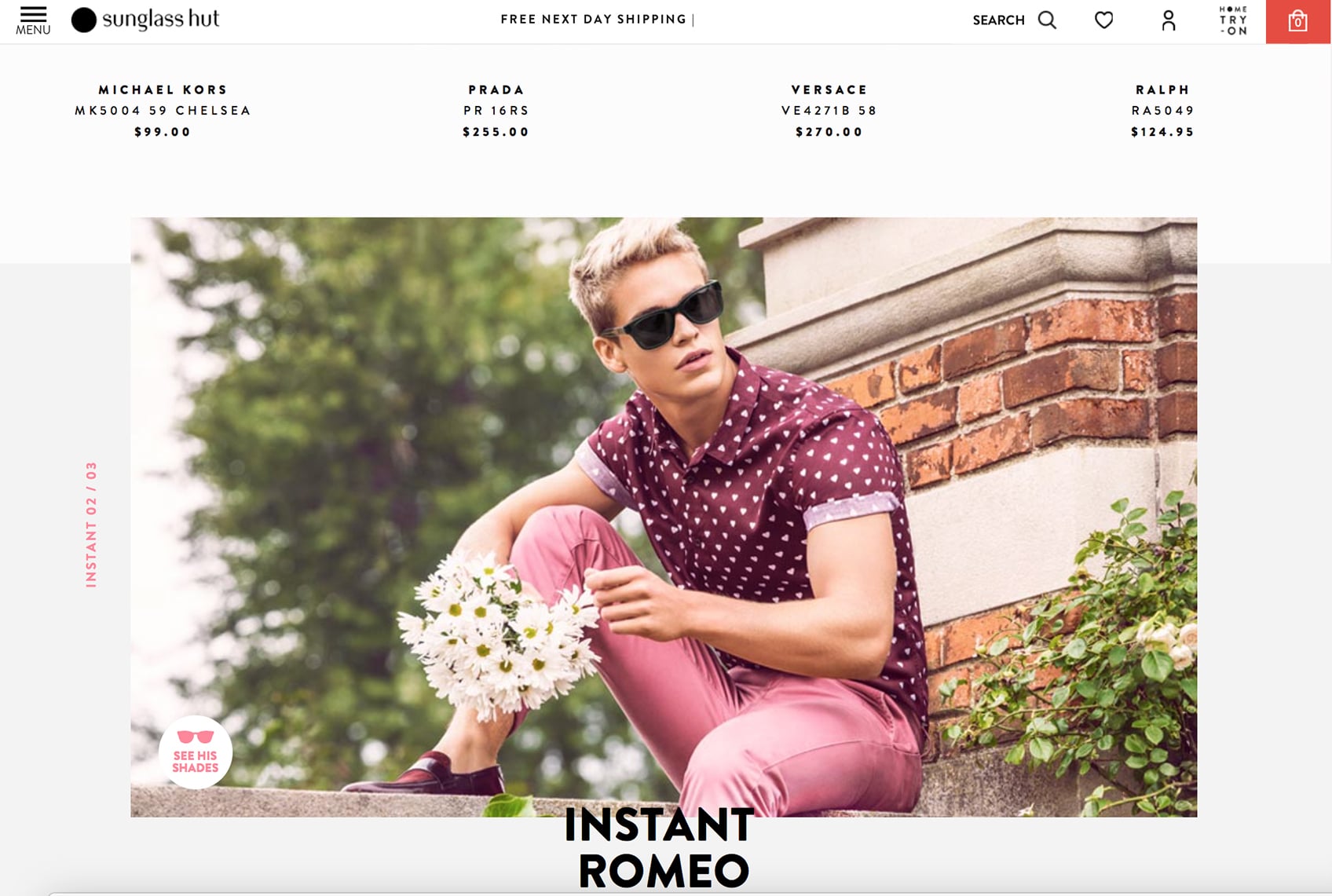

So it should really come as no surprise that when I received the above unsolicited e-mail for trendy sunglasses, my eyes quickly passed over the latest eyewear fashion (and the model in the pathetic pink and red clothing), and zoomed right in on the masonry wall in the background.

The wall looks like something constructed 100 years ago, and its formal shape is very appealing. But studying the wall more closely I realized that this brick and stone structure was a modern reinterpretation of a late 19th-century garden wall, and likely had been constructed within the last several years.

The biggest clues as to its true age were the sharp bevel cuts and crisp corners in the limestone capstones, and the size and texture of the bricks (this "modular" sized brick was not manufactured until the second half of the 20th century and its aged look has been achieved by adding a distressed red finish to an otherwise orange brick). It's a very well executed look, and nicely conveys a sense of enduring elegance.

Whether you're restoring a century old masonry structure or want to emulate the look of something from a bygone era, our licensed masons have the skills and experience to help.

Happy Valentine's Day and thank you for your support.

-Rob

Post: Happy 30th Anniversary to Frank Kruk!

Thursday February 4, 2016

We celebrated a meaningful milestone this week here at AAA-1 Masonry World Headquarters: Frank Kruk's 30th anniversary at the company!

Frank's name is synonymous with quality workmanship, integrity and patience. His expertise in this trade cannot be overstated, and he generously shares that expertise with his juniors—heck after 30 years on the job who isn't a “new comer” by comparison?

Frank started in the masonry restoration business 40 years ago and ran his own company, Fine Line, with his childhood friend Ken shortly after college (Ken's the guy in the back row of the photo, all the way on the right). Always ready for a challenge, Frank started shifting his attention to larger and more complicated masonry projects—you can read about some of these on our website—but has continued to dedicate considerable time to assisting homeowners with smaller repair projects like chimneys and stoop walls.

Frank's productivity is legendary. Despite the self-imposed workload, he is a supportive husband and father. (That's Frank in the front row, center, flanked by his wife, daughter and son, Dan, who joined the company 5 years ago).

Like the brick, stone and terra cotta he works with day in and day out, Frank is an enduring member of this company and the masonry restoration trade.

If you require masonry restoration work of the highest order, give us a call at 773-622-7300 and ask to speak to Frank. You'll be very glad you did.

Congratulations, Frank!

Post: Some Thoughts About Safety (#3 in a Series)

Wednesday January 20, 2016

This is the latest in an ongoing series of safety-related posts. See earlier entries Part 1 and Part 2.

While driving through the west side of Chicago recently, I passed by this building and was very disturbed by what I saw.

There are a number of really serious safety violations at this job site (the kinds that can lead to serious injury or death) and I thought it important to share my observations.

The first thing I noticed was the swingstage hanging from the top of the parapet wall. Even though this photo was taken from across the street, it is clear that this parapet wall is structurally compromised—look at the numerous applications of mortar applied (a cheap and short-lived method of repair), the loose and crooked capstones at the top of the building, and the green vegetation and SMALL TREE growing out of the parapet wall (about three feet below the capstones and just right of center of the swingstage)! So why in the world anyone hang a swingstage from the top of this compromised wall and expect to work safely? If this wall were to shift laterally, even slightly, the wall could collapse, and the swingstage and its occupants fall to the ground. OSHA considers any fall hazard greater than 6 vertical feet to be life-threatening, so this set-up is definitely unsafe. And what about all of those bricks falling on top of those injured workers? And what about the pedestrians walking under the swingstage, workers, and falling bricks?!? OSHA safety laws require that a swingstage be tied back to a secure immovable structure capable of handling the force generated by a fall by a factor of four in case of catastrophic failure, but I doubt those metal wall hooks at the top of the rigging are tied back to anything!

Then I noticed that this swingstage lacks a secondary braking system. Secondary braking systems are required in case the ropes from which the stage hangs (the yellow ropes on both ends of the board) fail or come loose. Without a secondary braking system the swingstage will free-fall should the ropes slip.

OSHA requires the presence of back rails to prevent workers from accidentally stepping off the swingstage. The "back rails" in this set-up appear to consist of a few pieces of 1" X 4" lumber tacked together. Completely inadequate and very unsafe! And where is the required kick board at the bottom of the stage to prevent tools and debris from falling off the stage and striking pedestrians below? And speaking of pedestrian safety, where is the required pedestrian canopy to protect passers-by from potentially catastrophic injury?

Maintaining a safe job site is of paramount importance at our company. We have a responsibility to our clients, to the public, to ourselves and to our families to safely perform our work and maintain a safe work environment. All of the masons at AAA-1 Masonry & Tuckpointing have passed Scaffolding Safety classes and maintain current certifications for fixed and swingstage scaffolding; every crew of masons is led by a foreman with over 25 years of hands-on field experience; and effective this year, every mason will have attended and passed an OSHA 10-Hour safety class.

With good training, thoughtful job site set-up and an awareness that comes from decades and decades of field experience, we mitigate work site hazards and provide you with peace of mind.

Be safe out there, and thank you for your support.

—Rob