After a good wind-driven rain, without fail the AAA-1 Masonry & Tuckpointing switchboard lights up with calls from condominium owners experiencing water leaks. Over 95% of the time, those leaks occur over a unit owner's rear bedroom balcony door or transom in a newer condominium building constructed within the last 15 years.

Usually, owners first become aware of the problem because water has pooled on the floor or, worse, has warped or buckled the floor boards. Sometimes the leaks are so severe that owners observe a steady stream of water flowing out of the wall above their door frames or transoms during a storm. In the photo at right, we have removed the damaged drywall to reveal a very wet concrete block wall with no insulation and an improperly constructed wood stud wall.

So why does this happen? Factors contributing to the leaks invariably include the following:

1. Extensive Use of Concrete Blocks in Lieu of Bricks

In the last 15 years or so, the use of high-quality brick has been replaced with larger, less dense and far more porous concrete blocks (aka Split Face Blocks). Developers like using these larger building materials because they drastically reduce the time required to construct a building's envelope. Depending on the depth of the block used, a single concrete block can replace the need to use up to 20 bricks. One concrete block versus 20 bricks?!? If you're a developer, the cost-saving choice is obvious. Usually developers will face the front of a building with more expensive and much denser brick in order to improve the building's curb appeal (any wonder, then, reports of water leaks in newer buildings are rarely reported on the front facade).

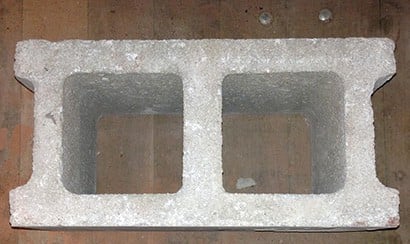

Not only is the density of the material used in concrete blocks far less than the density of the material used in traditional bricks, but concrete blocks are mostly hollow! (Refer to photo above right.) In general, wind-driven rain more easily passes through the walls of concrete blocks and therefore increases the likelihood of wet insulation, water stains, electrical shorts and damaged floors. That's bad!

2. Concrete Blocks Are Not Properly Sealed

Due to their porosity, concrete blocks need to be sealed. Sealants usually come in liquid form and are sprayed onto a wall. (Avoid applying sealants with a roller as this method does not effectively reach every nook and cranny of the block.) The type of sealant used and how much is applied makes a huge difference in its effectiveness and longevity. I will explain the differences between the many masonry sealants available in a future blog post, but know this: concrete blocks are not manufactured at the plant with sealant already in them. That's an urban myth — one that has been perpetuated by misguided real estate professionals and developers for nearly two decades. Due to the severity of Chicagoland's wind-driven wet weather events, concrete block walls must be sealed (after they are constructed), and this includes walls constructed with oversized utility bricks (which are nothing more than concrete blocks shaped to resemble bricks).

3. Improper Installation of Flashing

Flashing is a water-proof material used to direct water out of a wall. When properly installed, the flashing works as a barrier to prevent water from infiltrating the wall cavity and damaging your living space. When we do find flashing installed in concrete block walls, it is usually installed improperly or it is incomplete (e.g., the builder decided to install only 25 linear feet of flashing in a 50'-long wall). Well-intentioned developers are insisting their builders construct walls with the proper through-wall flashing detail over all window and door openings. Unfortunately, not all well-intentioned developers recognize a properly-installed flashing detail.

4. Installation of Deck or Balcony on Upper Floor

Very often there is deck or balcony one floor above the unit where the leak is observed. Look carefully and you will see that the deck or balcony is secured to the concrete block wall using through-wall fasteners called carriage bolts. Wherever you see a carriage bolt, water has the ability to infiltrate the concrete block wall and drip into the hollow wall cavity. Because most decks and balconies are built right up against the face of the building, it can be hard to see the water flowing down the carriage bolts and into the hollow concrete block wall…but it is happening!

What can you do to protect yourself from water damaging your home or investment?

1. Seal Your Building With the Best Masonry Sealant You Can Afford

The material should carry a written warranty and be applied when the masonry wall is bone dry. The sealant should have a moisture transmissivity rate >99%, which means the sealant allows the masonry wall to breathe while at the same time providing a hydrophobic barrier against wind-driven rain.

2. Request a Free Inspection from One of Our Licensed Mason Contractors

We are very qualified to determine whether your walls are properly sealed. We have applied millions of gallons of the highest-quality silane sealants to some of the finest masonry structures in the Chicagoland area. We know what works and the pitfalls to avoid if your building has been sealed in the past by a handyman or someone less qualified. Click here to request a free inspection of your walls.

From everyone at AAA-1 Masonry & Tuckpointing, thank you for your loyalty and trust.

—Rob

Post: Some Thoughts About Safety & Insurance

Thursday December 11, 2014

Just recently, I heard about the second fatal accident in Chicago in as many months involving unlicensed masons and improperly erected scaffolding. Had these men received the proper safety training, perhaps they would still be alive today.

All of AAA-1 Masonry & Tuckpointing's masons receive extensive and on-going safety training to protect the welfare of the workers, and the company is appropriately insured to protect the welfare of our customers.

Remember to always ask your mason for proof of insurance in the form a valid Certificate of Insurance (COI) before the job starts. On the COI there should be a phone number of the issuing broker, agent or company. Call that broker, agent or company and make sure the mason's coverages are, in fact, in place and the limits stated on the COI are, in fact, what the mason has on file with his insurance company. You do not want to discover after an accident that the certificate of insurance was fraudulent or had been terminated for non-payment or some other reason because that puts you—the innocent customer—at greater risk of being sued by the injured party.

If you have questions about what kind of insurance your masonry restoration should be carrying or the appropriate limits, please give us a call and we'll walk you though it.

Thank you for the opportunity to be of service!

Post: Why Temperature Matters At This Time of Year

Tuesday November 11, 2014

Our crew of hard-working masons continue to work despite the cold because the site is wrapped in heavy-duty weather protection and the heaters are permitted to run day and night.

Peter and Mark stand in front of their freshly-constructed foundation wall despite the freezing temperatures outside. Ambient temperature inside the protected work site remains constant at 50 F.

This week's Arctic blast of unseasonably cold weather has brought night time temperatures down into the teens — and that's before the windchill gets factored in…that's cold! Historically, this part of Illinois doesn't experience consistent hard freezes until early December, so the unseasonably cold weather has caught many masonry restoration companies by surprise.

Yet despite the extreme cold, this week I have seen many masonry restoration companies continue to work. This is really unfortunate for the consumer since curing mortar is very sensitive to cold temperatures. If night time temperatures should dip below 26 degrees, then the tuckpointing and brick work will suffer. (Starting at this temperature, the water in curing mortar begins to freeze, and if that happens the longevity of the work becomes severely compromised—even though it may look fine to the naked eye for a season or two.)

Some masonry companies add anti-freeze to reduce the freezing point of the water in their mortar, or they add accelerants to the mortar to make it dry faster. Unfortunately, both strategies lead to a finished product whose bonding properties, resistance to wind-driven weather, and overall longevity are compromised—sometimes severely.

There are only two ethical ways a masonry company can accommodate colder temperatures—either heat the job site day and night until the mortar cures, or suspend the project until the spring when night time temperatures rise out of the danger zone.

Many masonry companies heat their job sites with liquid propane or kerosene while they are working, and then take their heat source home with them when they pack up for the day. This leaves the curing wall vulnerable to sub-freezing temperatures at night when temperatures are likely to be the coldest. Not a wise strategy. At a current job in Carpentersville, AAA-1 Masonry & Tuckpointing is continuing to rebuild 100-year-old brick walls despite the cold because the owner has elected to tarp in the work area and run two natural gas heaters day and night (the heaters are hard-piped to the building's gas line).

Remember, the temperatures which matter the most are the night time temperatures (i.e., the coldest part of the day/night cycle). Temperatures which dip much below 26 degrees will have a deleterious effect on the curing mortar's bonding properties, resistance to wind-driven weather and longevity — unless the job site is heated day and night until the mortar has cured.

To learn more about our honest approach to masonry restoration work, please give us a call or send us an e-mail.

Stay safe.

-Rob

Post: Kudos to Frank Kruk

Monday September 15, 2014

Kudos to AAA-1 Masonry & Tuckpointing's veteran project manager, Frank Kruk, for starting the second phase of work on the Daniel Burnham-designed Randolph Place condominium building in Chicago!

Due to this building's age, positioning of retro-fitted steel balconies, multi-level roof design, and busy Chicago traffic below, this project has been a fun challenge for Frank, who is recognized as one of the industry's most experienced licensed masons.

In the photo aboveat right you can see how Frank and the men have set up their swingstages at the top of the building, while heavy-duty pedestrian canopies and debris nets are positioned below.

AAA-1 Masonry & Tuckpointing applies the same experience and energy restoring legendary century-old structures like Randolph Place as it does your family's brick three-flat or your mother-in-law's concrete block condominium. With over 60 years of continuous experience, we possess the skills needed to restore your masonry structure back to its original, glorious condition.

Give us a call and we'll explain how.

Post: Counting My Blessings!

Thursday July 31, 2014

A few months ago I had the opportunity to bring my daughter to work as part of her school’s Take Your Child to Work Day. My seven year old, Charlotte, really enjoyed the opportunity to see what her father does for a living and watch AAA-1 Masonry’s licensed masons in action. Scaffolding was erected, mortar mixers turned and turned, men shouted out orders for more bricks and mortar, and Charlotte had the chance to see exemplary masonry restoration work in real time. We drove to Bucktown, Wicker Park, Hyde Park and the North Shore during our day together. It was a memorable experience for both of us, and she slept very well that night!

This past weekend, I had the opportunity to bring my five-year-old son, Harrison, to work during the morning hours. (We work every day the weather allows Monday - Saturday.) Wow, did he have fun! Prior to the men starting the construction of a new section of wall in Edison Park, Harrison was allowed to hold a few bricks and pretend he, too, was a mason. We talked about the different size bricks we use (Standards, Modulars, Romans, etc.), the different types of mortars we use depending on the application, and the importance of maintaining a safe and clean job site.

The best part of the day, though, came at bath time when Harrison shared with me that he wants to do exactly what I do when he gets older. Those were the nicest words this Daddy mason could hear! Might there be a third-generation mason at our little masonry restoration company in the not-so-distant future?!?

Thank you to all of our loyal clients for your continued patronage and numerous compliments!