Stories From the Field

- Making Ready for the 2025 Season (03/19/25)

- A Tribute to Howard Reese (January 3, 1944 - April 8, 2022) (04/08/22)

- Scaffolding Saves the Day (09/20/21)

- Reputation for Honesty & Integrity (07/16/21)

- We Leave Your Masonry Restoration Project Debris Free (06/18/21)

- Window Lintel Replacement Work in East Lakeview (05/28/21)

- An On-going Commitment to Safety (04/24/21)

- AAA-1 Masonry Goes International (04/01/21)

- Quality Work That Will Last For Generations (12/10/20)

- The End of the Work Season Approaches (11/20/20)

- Exceptional Masons Produce Exceptional Masonry Work (09/24/20)

- Changing of the Season (03/08/20)

- The Seasonality of the Masonry Restoration Trades (12/20/19)

- AAA-1 Masonry In A Nutshell (11/20/19)

- No Project Too Big or Too Small (11/08/19)

- What Sets Us Apart (10/19/19)

- Heavy-Duty Vinyl Tarpaulins - An Affordable Means of Stopping Water Infiltration Through Your Masonry Walls (10/01/19)

- Glass Block Windows (06/12/19)

- The Impact of Our Erratic Spring Weather (05/10/19)

- Many (Skilled) Hands Make Light Work (04/19/19)

- Recipient of the 2018 Angie’s List Super Service Award (03/15/19)

- Prohibition-Era Building Materials (01/31/19)

- Recipient of the 2017 Angie’s List Super Service Award (02/01/18)

- Repairing Mortar Joints in Lakeview (08/27/17)

- What's That Haze On My Bricks? (08/15/17)

- Grinding & Tuckpointing (07/14/17)

- Some Thoughts About Safety (#5 in a Series) (03/15/17)

- Masonry Restoration Work & Cold Weather Considerations (#2 in a Series) (02/13/17)

- Masonry Restoration Work & Cold Weather Considerations (#1 in a Series) (01/20/17)

- An Industry In Growing Demand (12/20/16)

- Some Thoughts About Safety (#4 in a Series) (07/28/16)

- "High Quality" Masonry Sealers (06/20/16)

- Personal Protective Equipment (PPE) (05/18/16)

- Chimney Restoration in Hinsdale (04/30/16)

- Ask the Hard Questions (04/16/16)

- Masonry Restoration Case Study (04/06/16)

- Unique Flashing Detail (03/21/16)

- Valentine's Day Truth (02/14/16)

- Happy 30th Anniversary to Frank Kruk! (02/04/16)

- Some Thoughts About Safety (#3 in a Series) (01/20/16)

- Masonry Restoration at Second Church of Christ, Scientist (12/28/15)

- Expression of Gratitude (12/11/15)

- The Importance of Conducting Annual Inspections (11/25/15)

- Proper Site Protection Worth Every Cent (11/05/15)

- Former Dairy Undergoes Masonry Transformation (Part 2) (10/31/15)

- Unusual Brick Discovered (09/30/15)

- New Parapet Wall Project in East Ravenswood (09/16/15)

- Former Dairy Undergoes Masonry Transformation (Part 1) (07/14/15)

- Some Thoughts About Safety (#2 In a Series) (07/02/15)

- Some Thoughts About Safety (#1 In a Series) (06/29/15)

- Enduring Masonry in Oak Park (06/20/15)

- Whatever the Job Requires! (06/15/15)

- Residential Chimney Project in Glencoe (06/02/15)

- AAA-1 Masonry & Tuckpointing is Your Restoration Company (05/09/15)

- Restoring Fourth Presbyterian Church's Historic Fountain (04/06/15)

- Water Leaks – Sound Familiar? (01/15/15)

- Some Thoughts About Safety & Insurance (12/11/14)

- Why Temperature Matters At This Time of Year (11/11/14)

- Kudos to Frank Kruk (09/15/14)

- Counting My Blessings! (07/31/14)

- Your Brick Structure Can Last Another 100+ Years with Preventative Maintenance (07/08/14)

- Masons Are Like Farmers (06/13/14)

- Look Up! (05/28/14)

- Bring Your Child to Work Day (04/24/14)

- AAA-1 Masonry & Tuckpointing Receives BBB's 2013 Complaint-Free Award (02/28/14)

- Heavy Duty Tarps: Effective, Durable Solution for Winter Leaks (02/18/14)

- Why Weather Matters (01/27/14)

- A Few Thoughts About Quality (12/10/13)

- If You Build It Right the First Time... (09/01/12)

- More Common Than You Think (07/06/12)

- Flashing or Through-Wall Flashing (05/05/12)

- Extensive Edison Park Office Project (Underway) (04/24/11)

- Wright Chimney Restoration (03/15/11)

- Lincoln Park Residential Restoration (09/09/10)

- Critical Facade Inspection Work (08/15/10)

- Residential Chimney Rebuild (07/01/10)

- Vehicular Impact With Building (07/20/09)

- Taken For A Ride (06/15/09)

- Chronic Water Damage (05/10/09)

- Brick Wall Repair (11/15/08)

Stories From the Field

Post: "High Quality" Masonry Sealers

Monday June 20, 2016

A client whose masonry home we repaired back in 2014 recently requested an inspection of a just-constructed home in the Bell School neighborhood that he was interested in purchasing for his family. The home was really lovely, the floors gleamed, the walls were pristine, and it had GREAT curb appeal.

But closer inspection of the building’s envelope revealed a lot of short cuts. Most disturbing was the admission by the developer (after constant hounding for clarification) that the exterior brick walls were constructed with only a single wythe of brick with stick-frame construction behind it. With a price tag of almost $2 million that was a big disappointment. I would have expected the walls to be comprised of a minimum of two wythes of real brick (i.e., no cinder block back-up). The quality of the brick selected for the project was also a disappointment because the developer felt the need to seal it with a “high-quality sealer.”

Masonry sealers are used to provide a hydrophobic barrier against wind-driven rain. (Learn more about masonry sealers in the ‘Services’ section of the website.) Masonry sealers are critically important for newer buildings constructed with a single wythe of brick or cinder block (also known as split-face block).

The term “high-quality sealer” means little in our business. Sales reps from masonry yards will tell you they only sell “high-quality masonry sealers” (why would they sell low quality products, right?) but these products do not hold up for very long against our Chicagoland wet weather events and should not be seriously considered.

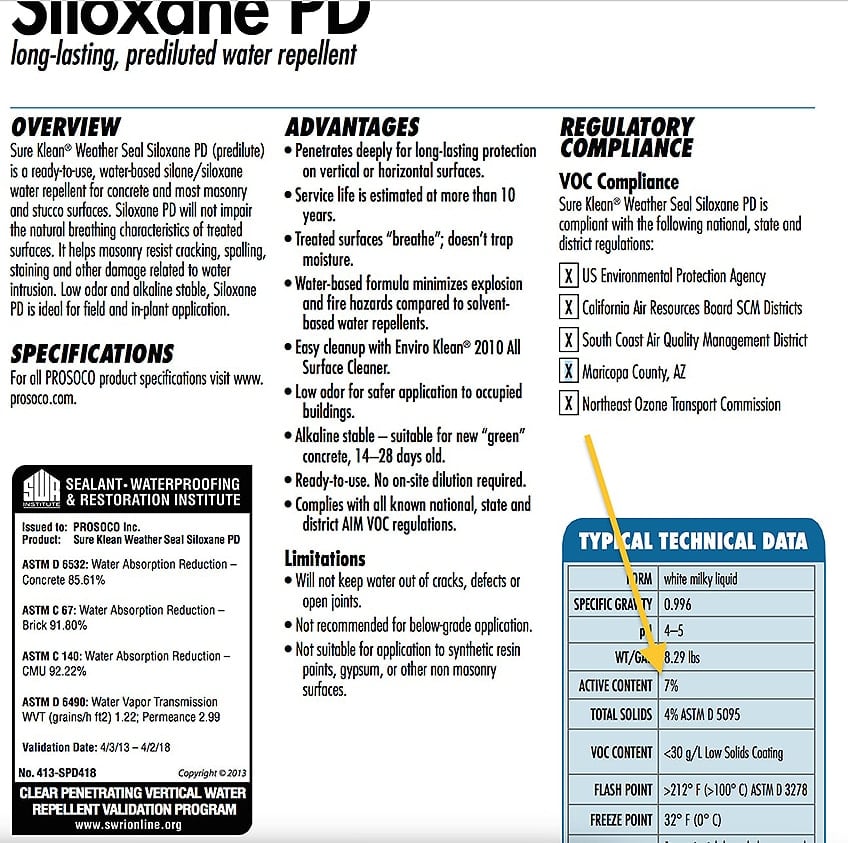

Eventually, the developer sent my client this promotional data sheet, which describes in more detail the masonry sealer he used. I was pleased to see that the active ingredient in this sealer was silane. Silane is the most effective substance you can apply to a masonry building, allows the walls to retain a moisture transmissivity rate in excess of 99.9% (so the walls breathe as though nothing at all had been applied), and when applied in sufficient quantity provides the very best protection against wind-driven rain events.

Unfortunately, the percentage of active ingredient in this product was only 7%. That is regrettably low. AAA-1 Masonry & Tuckpointing uses only 100% silane solutions. Years ago, we offered a 40% silane solution to our more price conscious clients. (So even our price sensitive clients received a product containing over 5-1/2 times the amount of active ingredient as the sealer applied by this developer to his very expensive home.)

While the percentage of active ingredient is a crucial component to ensuring a long-lived sealing job so, too, is the amount of sealer applied. There is no legal minimum application rate at which developers and masons must apply their sealers. That means developers can apply one gallon of sealer over 500 ft2 of a masonry wall and deem it “sealed,” whereas AAA-1 Masonry typically uses 1 gallon of sealant over an area more like 75 ft2 of masonry wall.

I have yet to find out if my client decided to go ahead with the purchase of the home, but I hope he didn’t.

If you need an honest and thorough assessment of the true quality of your masonry dream house, please give us a call.

-Rob